Mazak Quick Turn 15N

“World’s Fastest CNC Lathe”

Equipped with a Mazatrol T-32 Computer Numeric Controller, this system features highly accurate machine control and the ability to check programs to ensure quality parts. It also provides unsurpassed productivity and exceptional quality for medium to large lots as well as small lot production because of its superior mechanical design.

UNSURPASSED MACHINING ACCURACY

- Continuous Maching Accuracy: within (0.003 in.)

- Roundness within (0.00003 in.)

- Surface Finish within (0.00003 in.)

SPECIFICATIONS

- Maximum Cutting Diameter 300 mm (11.81 in.)

- Maximum Machining Length 500 mm (19.69 in.)

- Maximum Bar Work Size (spindle thru) 51mm (2 in.)

- Programmable Tailstock

FULL MACHINE LISTING

- Mazak Q.T. 6 Flex GL-6 equipped with fully automated gantry load/unload system

- Mazak Q.T. 250 8″ chuck with tail stock

- Mazak Q.T. 8S.P. 6″ chuck with sub spindle & loading robot

- Mazak Q.T. 8N 6″ chuck with tail stock and auto bar feeder

- Mazak Q.T. 8N 6″ chuck with tail stock

- Fadal V.M.C 15 16″ x 20″ x 16″ vertical machining center

- HAAS VMC Mini Mill 12″ x 16″ x 20″ vertical machining center

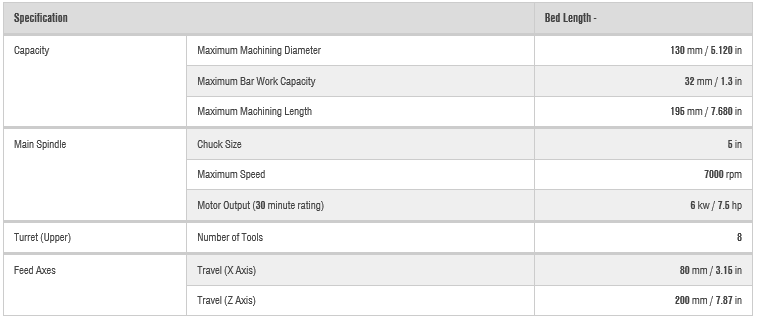

Mazak 6 Gentry Loader Full Specifications

ADDITIONAL MACHINES and OFFERED SERVICES

- 15″ Clausing Clochester Engine Lathe, with 16 position turret and finger collets

- 12″ Clausing Lathe: Variable Speed Spindle, with 6 position turret and air collets

- 2 Bridgeport Milling Machines, with power feed and digital readout

- Harding Super Precision Horizontal Milling Machine

- Full complement of Drill Presses, Grinders, Sanders and Supporting Tools and Tooling

- On-staff Mechanical Engineer

- Expert Welding: MIG, TIG & Stick welding of steel, stainless aluminum and castings

- Wood and Aluminum Pattern and Mold Work

Along with full machine toolsets, we perceive Quality Control, Customer Service, Capacity, and Value Pricing essential ingredients to successful partnerships.

QUALITY CONTROL: Structures Company has specific quality control SOP’s in place to ensure we are meeting our customer’s needs. Through assessing our customer’s quality expectations, we have been able to set up unique systems and production guidelines to maintain strict machining tolerances.

CAPACITY PLANNING: we have purchased additional turning centers with integrated automation to increase our production capabilities.

CUSTOMER SERVICE: as a small to medium size production resource, we’re able to provide customized services strategies to accommodate our customers unique needs, from maintaining an on-going inventory of parts to providing emergency services. Structures delivers quality products in a timely manner, with exceptional service.

VALUE PRICING: we are focused on providing our customers with high quality products and services, and accomplish this through maintaining low overhear while employing a skilled workforce. We’re positive you will find our prices and value to be the vest in the area.